Cylinders

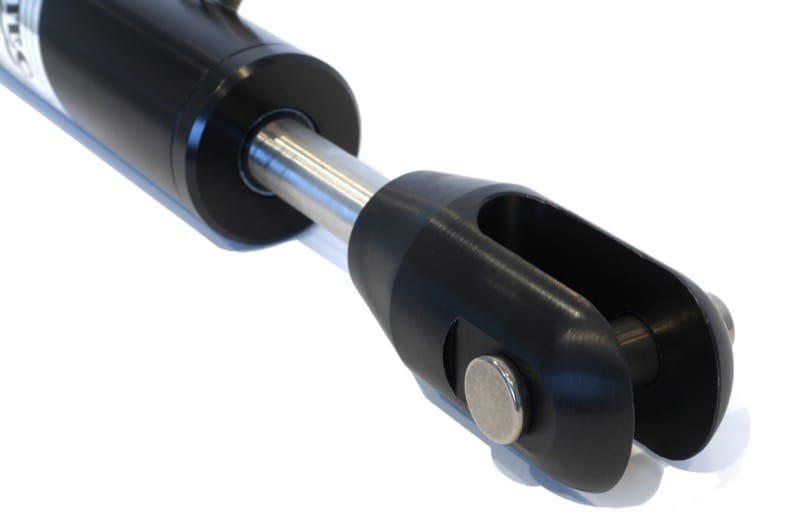

SAILTEC has designed its cylinders to be reliable, long-lasting, and efficient. SAILTEC has done this by using high-strength aluminum alloys and advanced manufacturing techniques. SAILTEC also uses Molyguard bearings on the piston and the upper end to ensure cylinder and piston rod scoring does not occur while under side load.

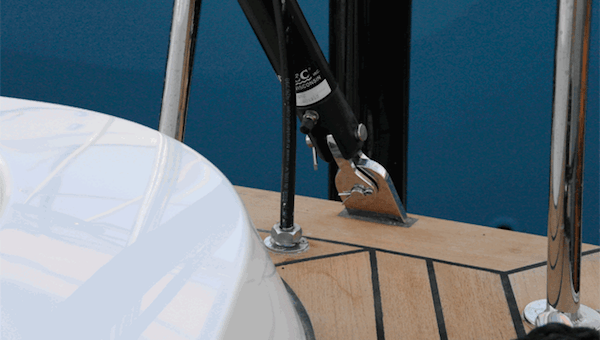

SAILTEC cylinders are available in three standard stroke lengths with pneumatic return or double-acting feature. Aluminum upper jaws are standard on all cylinders. All exterior surfaces are hard anodized for greater corrosion resistance, and to retain their attractive appearance for many years of service.

The SAILTEC Locking Option is available on both standard and long-stroke cylinders. This mechanical device locks the cylinder in position, thus allowing the release of hydraulic pressure. Also, the threaded lock rod can be marked for upwind and downwind positioning.

SAILTEC cylinders are designed to pull (typically), push, or both with common applications such as backstays, forestays, outhauls, and travelers. SAILTEC cylinders have proven to be reliable, long-lasting and efficient. High-strength aluminum and T-316 stainless alloys and state-of-the-art manufacturing techniques result in precision, zero-leak cylinders with even seal loads and minimal seal wear. The upper jaw, lower jaw and cylinder are made of high-strength, heat-treated aluminum alloy, precision-honed and polished for appearance.

The stock cylinders available can also be custom built with polished T-316 steel, custom stroke lengths to 100" (2,500mm), threaded rod ends for turnbuckle bodies, and configured to pull hydraulic/push pneumatic or push/pull hydraulically.