The release valve must is open. Is the valve stem, knob damaged?

Can you rotate / turn the piston rod? When trying to rotate the rod, is there on area where it is harder to turn? The piston rod may be bent if does not rotate freely.

Are you pulling the rod with enough force? When the Integral is new, everything is very tight and requires a lot of force. For example the smallest Integral, -08 needs 30 lbs. of pull to break away friction. A -30 needs over 200 lbs.

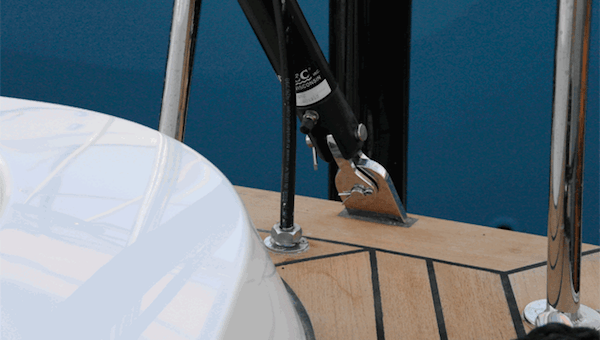

To manually gain purchase, remove clevis pins and thread a rod (a huge screw drive or metal dowel) through the clevis pin hole. Do this at the top end (Upper Jaw) and at the bottom end (Lower Jaw). You can plant your feet on the bottom dowel. This makes it easier to pull the rod out.

If the piston rod is "frozen" that is probably due to galvanic corrosion where the stainless rod "adheres to the aluminum cylinder. This happens when the wiper seal which sits on top of the cylinder and clean contaminates off the rod when it goes into the cylinder is

worn, cracked, extruded or simply missing.

This Integral needs service now.

Sail Faster with SAILTEC

SAILTEC, Inc. has specialized in designing and building hydraulic tension and rig control for sailboats and custom marine hydraulics since 1983. Our cost effective and durable hydraulic solution, coupled with a serious dedication to customer service and product support has made SAILTEC the first production boat source for many top sailboat brands for over twenty years.

We manufacture hydraulic/pneumatic cylinders, hand pumps, and 12V & 24V electric pumps that operate to 5000 psi (350 bar) and can generate up to 100 ton of force. Our latest products include hydraulic control of hatches, transom doors, swim platforms, keel lifting, radar lifts and other specialized applications.

SAILTEC is the sailing industry's preference for marine hydraulics offering:

- Worldwide sales and service

- Standard and custom cylinders

- Exceptional factory support

- Product innovation

Better performing products at a lower price, SAILTEC is a great value

- Light-weight cylinders and pumps

- Larger piston rods for longer life and resistance to side loads

- Redundant seals for extra leak prevention and longer life

- Faster pumping speeds than comparable models in the industry

- Competitive pricing

- Broad range of cylinders, integrals and pumps with respect to stroke, speed, fit and function